Direct Repair Programs (DRPs) enhance automotive repair efficiency, reducing downtime and costs for high-end brands like Mercedes Benz. Structured protocols and specialized training allow DRPs to handle complex tasks swiftly, improving customer satisfaction in collision and dent repairs. Efficient operations enable businesses to manage growing volumes and thrive in competitive markets, with faster service times, reduced wait times, and continuous improvement based on tracking parts usage and labor costs. Measuring success beyond repair counts shows cost savings and enhanced quality, strengthening the automotive collision repair network.

In today’s competitive market, efficiency is the key to unlocking success in direct repair programs. These initiatives, designed to streamline vehicle repairs and enhance customer satisfaction, require meticulous planning and execution. This article explores why efficiency acts as a driving force behind sustainable direct repair programs. We delve into its role in optimizing operations, ensuring long-term viability, and highlighting how increased efficiency translates into tangible results and improved performance metrics for all stakeholders involved.

- Direct Repair Programs: Streamlining for Success

- Efficiency's Role in Program Sustainability

- Measuring Impact: Results Driven by Efficiency

Direct Repair Programs: Streamlining for Success

Direct Repair Programs (DRPs) are designed to streamline the vehicle repair process, ensuring efficiency and effectiveness from start to finish. By implementing structured protocols and specialized training, DRPs enable repair facilities to handle complex repairs with precision and speed. This streamlined approach is particularly beneficial for high-end vehicle brands like Mercedes Benz, where meticulous craftsmanship and original equipment parts are paramount.

For instance, in the event of a vehicle collision or dent repair, a well-organized DRP facilitates quick assessment, accurate damage estimation, and efficient parts procurement. This not only reduces downtime but also minimizes costs, enhancing customer satisfaction. The focus on efficiency allows repair facilities to manage increasing volumes of repairs, turning challenges into opportunities for growth and success in competitive markets, such as the automotive industry where vehicle dent repair is a common service request.

Efficiency's Role in Program Sustainability

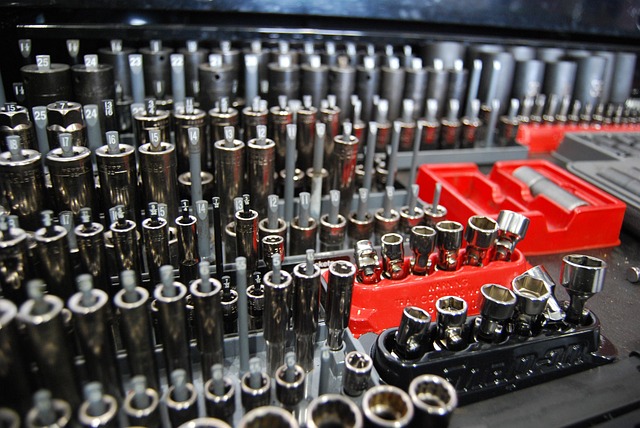

Efficiency is the backbone that sustains direct repair programs (DRPs). When a DRP operates with streamlined processes and optimized workflows, it ensures that each step from intake to completion is executed in the most time- and cost-effective manner. This not only enhances overall program performance but also fosters sustainability. By minimizing delays and maximizing resource utilization, the program can maintain consistent service levels without overextending personnel or financial resources.

Consider the impact of efficiency on a DRP’s ability to handle various services, such as auto glass replacement, vehicle bodywork repairs, and scratch repairs. Efficient processes ensure that these tasks are completed promptly, reducing customer wait times and enhancing satisfaction. Moreover, efficient operations allow for better tracking of parts usage, labor costs, and overall program metrics, providing valuable insights to continuously improve and adapt to evolving needs in the automotive repair landscape.

Measuring Impact: Results Driven by Efficiency

In the realm of direct repair programs, efficiency is a game-changer that drives success. Measuring the impact of these programs isn’t merely about counting the number of repairs completed; it’s about quantifying the results and the positive outcomes they yield. Efficient direct repair programs streamline processes, minimizing time and resources spent on each car dent repair or automotive collision repair. This, in turn, translates to cost savings for both the repair shop and the insurance company, ensuring that automotive repair services are provided swiftly and effectively.

By focusing on efficiency, these programs enhance customer satisfaction through faster turnaround times and reduced costs. The ability to handle a higher volume of repairs without compromising quality sets successful direct repair programs apart. This level of efficiency not only benefits individual repair shops but also fosters a robust network of automotive collision repair services, ultimately contributing to the overall success and resilience of the industry.

In conclusion, efficiency is the cornerstone of successful direct repair programs. By streamlining processes and optimizing resources, these programs can achieve long-term sustainability and deliver measurable results. This focus on efficiency ensures that direct repair initiatives not only reduce costs but also enhance overall program effectiveness, ultimately benefiting both businesses and consumers alike.