Direct repair programs (DRPs) gain popularity across industries for efficient, cost-effective repairs, initially in automotive, now expanding to electronics, furniture, and aerospace. DRPs streamline processes, reduce waste, extend product lifespans, promote sustainability, and enhance convenience in urban areas by optimizing vehicle damage management. The global automotive industry shifts towards DRPs for frame straightening and body work, with projections for wider integration due to electric vehicles and environmental concerns.

Direct repair networks, or direct repair programs (DRPs), have gained significant traction across various industries due to their cost-effectiveness and efficiency. This article explores where DRPs are most widely adopted, focusing on industry sectors that embrace these programs. We delve into the advantages in urban areas and metro cities, and examine global adoption trends and future projections. By understanding these key aspects, businesses can harness the power of direct repair for improved operational strategies and enhanced customer satisfaction.

- Industry Sectors Embracing Direct Repair Programs

- Advantages in Urban Areas and Metro Cities

- Global Adoption: Trends and Future Projections

Industry Sectors Embracing Direct Repair Programs

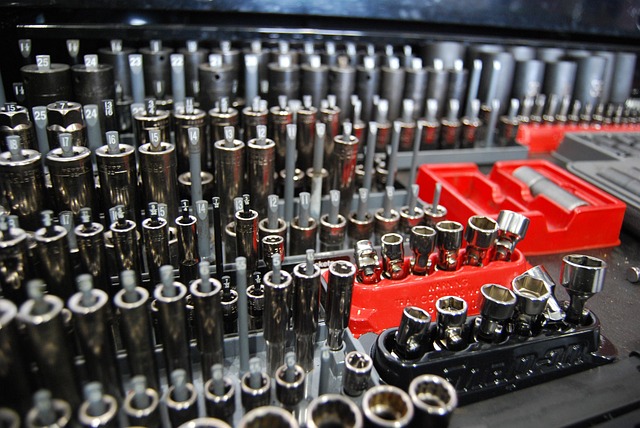

The adoption of direct repair programs is gaining traction across various industry sectors, recognizing the benefits of streamlined, efficient, and cost-effective repair processes. These programs are particularly popular in the automotive sector, where they have revolutionized the way vehicle damage is addressed. Instead of traditional collision repair methods that can be time-consuming and costly, direct repair networks enable faster and more localized repairs for a wide range of issues, from minor scratches and dents to major accidents.

In addition to the automotive industry, sectors such as electronics, furniture, and even aerospace are embracing direct repair programs. The approach is particularly advantageous for managing complex supply chains and reducing waste. For instance, in the case of electronic devices, direct repair can extend product lifespans, decrease e-waste, and offer consumers more sustainable options. Similarly, for furniture and other consumer goods, direct repair networks promote longevity, reducing the need for frequent replacements and fostering a culture of sustainability.

Advantages in Urban Areas and Metro Cities

In urban areas and metro cities, direct repair networks offer significant advantages due to their ability to streamline auto repair services. The dense population and high vehicle ownership in these regions create unique challenges, such as heavy traffic congestion and limited parking spaces. Direct repair programs address these issues by facilitating faster turnaround times for car paint repairs and fender bender fixes. By establishing a network of pre-screened and certified repair shops, these programs ensure that drivers can quickly get their vehicles back on the road without navigating through lengthy waiting periods or high costs often associated with traditional auto repair services.

Moreover, direct repair networks enhance customer satisfaction by providing convenience and peace of mind. Insured drivers involved in minor accidents or requiring routine maintenance can choose from a network of trusted facilities, knowing that their repairs will be handled efficiently and within their insurance company’s guidelines. This centralized approach not only simplifies the claims process but also encourages safety by promoting timely repairs, reducing the number of vehicles on the road with outstanding repairs, and, ultimately, contributing to better road conditions in these bustling urban landscapes.

Global Adoption: Trends and Future Projections

The global adoption of direct repair programs (DRPs) has been on an upward trend, driven by a growing awareness of sustainability and cost-effectiveness in the automotive industry. This model, which emphasizes specialized networks for car repair shop frame straightening and automotive body work, is increasingly seen as a game-changer in managing vehicle repairs. As of recent years, many regions have witnessed a surge in DRP participation, with more automakers and insurance providers partnering to streamline the process.

Looking ahead, future projections indicate an even wider integration of direct repair networks. The shift towards electric vehicles and autonomous driving technologies is expected to further propel this trend, as these innovations require specialized tools and techniques for repairs, which DRPs are well-positioned to provide. Moreover, with growing environmental concerns, the focus on eco-friendly practices in car repair shops will continue to shape the adoption of direct repair programs, ensuring a more sustainable future for the industry.

Direct repair programs have gained significant traction across various industries, particularly in urban areas and metro cities, where their advantages are most prominently felt. As global adoption continues to rise, these programs are poised to revolutionize the way we approach repairs, fostering sustainability, cost-efficiency, and convenience. By embracing direct repair networks, businesses can contribute to a more eco-friendly future while enhancing customer satisfaction.