Consistency in direct repair programs (DRPs) is vital for maintaining uniform quality standards, customer satisfaction, and fair evaluations across all stages of vehicle bodywork services. Standardized procedures enable informed decision-making, track program updates, and ensure better collision repair outcomes through data-driven performance measurements.

Consistency is a cornerstone of successful direct repair programs (DRPs). This article explores how maintaining consistent processes, from estimate approval to final inspection, significantly influences DRP evaluations. We delve into the critical role consistency plays in evaluation methods, highlighting its profound impact on outcome measures such as customer satisfaction, cost savings, and program efficiency. By understanding consistency’s role, DRP managers can optimize their programs for better performance and enhanced results.

- Understanding Consistency in Direct Repair Programs

- The Role of Consistency in Evaluation Methods

- Measuring Success: Consistency's Impact on Outcomes

Understanding Consistency in Direct Repair Programs

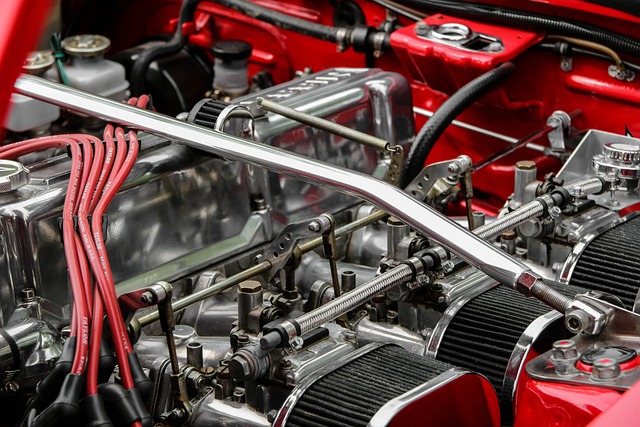

Consistency is a cornerstone in evaluating any program, especially direct repair programs (DRPs). In the context of DRPs, which are designed to streamline and manage vehicle repair processes, consistency refers to uniform application of procedures, standards, and quality measures across all stages of car bodywork services. This encompasses everything from initial assessment and diagnosis to final inspection and handover. A well-structured DRP maintains consistency through clear protocols, ensuring that every automotive body shop within the network adheres to the same high standards.

This uniformity is vital for several reasons. Firstly, it guarantees customers receive comparable service quality regardless of which shop they visit. Secondly, it simplifies training and onboarding processes for new employees or shops joining the DRP network. Lastly, consistent procedures facilitate efficient data collection and analysis, allowing for more accurate performance evaluations and continuous improvement initiatives within the automotive body shop ecosystem.

The Role of Consistency in Evaluation Methods

Consistency plays a pivotal role in the evaluation methods employed within direct repair programs. When assessing the performance of a collision repair shop or center, having standardized procedures and criteria ensures fairness and accuracy across all evaluations. This is particularly important in the automotive collision repair industry, where the quality of repairs directly impacts customer satisfaction and safety on the road. By maintaining consistency, evaluators can compare results objectively, allowing for a clear understanding of the program’s strengths and areas that require improvement.

In terms of direct repair programs, consistent evaluation methods enable stakeholders to make informed decisions based on reliable data. This is essential when considering the overall success of these initiatives, as it helps identify best practices that can be replicated across different collision repair centers. Moreover, consistency ensures that any changes or updates to the program are effectively tracked and measured, providing a comprehensive view of its evolution and impact on the automotive industry.

Measuring Success: Consistency's Impact on Outcomes

Measuring success in any direct repair program hinges on consistency, a linchpin that ensures outcomes align with expectations. When automotive repair shops maintain uniform processes and quality standards, it translates to better customer satisfaction and more consistent vehicle collision repair results. This uniformity isn’t just about following checklists; it involves training staff consistently, adhering to set protocols for car paint services, and ensuring every step in the repair process is executed identically.

Consistently applied methods foster predictability, allowing for precise tracking of program effectiveness. By measuring key performance indicators (KPIs) such as repair time, cost efficiency, and customer feedback, shops can identify areas for improvement and highlight achievements. This data-driven approach enables them to fine-tune their direct repair programs, ultimately enhancing overall service quality in both vehicle collision repair and routine automotive maintenance.

Consistency is a cornerstone of successful direct repair programs, influencing evaluation methods and ultimately shaping outcomes. By ensuring uniform standards and processes, organizations can accurately assess and improve their initiatives. This not only enhances the efficiency of repairs but also fosters trust among stakeholders. Incorporating consistency into direct repair program evaluations is a strategic move that leads to better-informed decisions and enhanced overall performance.