Thoroughly understand your direct repair program (DRP)'s unique guidelines and processes to streamline estimates, ensure compliance, and boost productivity in your auto body shop. Optimize procedures, use digital software for faster data input and report generation, integrate specialized training, and foster efficient communication for seamless workflows that benefit both the shop and customers with quicker turnaround times. Leverage technology in DRPs for automated tasks, real-time data access, and improved repair quality, reducing paperwork and manual calculations. Standardization across repair facilities fosters trust with fair, transparent estimates.

Looking to boost your estimate speed in direct repair programs? This guide breaks down how to optimize your processes and leverage technology. First, understand your DPR requirements and streamline key steps for faster turnarounds. Next, explore tech tools that enable accurate, rapid evaluations, revolutionizing how you handle repairs. By implementing these strategies, you’ll enhance efficiency, meet customer expectations, and excel in your direct repair program.

- Understand Your Direct Repair Program Requirements

- Streamline Processes for Faster Estimates

- Leverage Technology for Accurate, Rapid Evaluations

Understand Your Direct Repair Program Requirements

Before tackling how to improve estimate speed, it’s crucial to understand the specific requirements of your direct repair program (DRP). Each DRP has its own set of guidelines and processes that must be followed, so taking the time to comprehend these intricacies is vital for efficient auto body repairs. Familiarize yourself with the policies regarding frame straightening, parts sourcing, and documentation. Knowing these ins and outs allows you to streamline your estimate process, ensuring compliance while enhancing your productivity in the automotive body shop.

Moreover, understanding DRP requirements enables you to anticipate potential bottlenecks. For instance, if certain procedures require specialized equipment or specific training, plan accordingly to avoid delays. Efficiently managing these aspects contributes significantly to faster estimate generation and overall service delivery in auto body repairs.

Streamline Processes for Faster Estimates

Streamlining processes is a key strategy to significantly enhance estimate speed within direct repair programs. By optimizing each step of the estimation process, from initial inspection to final documentation, auto body shops can reduce time-consuming tasks and improve overall efficiency. Implementing standardized procedures ensures that estimators follow a consistent approach, minimizing deviations that may slow down the process. Digitalization plays a pivotal role here; adopting advanced software solutions for estimating allows for faster data input, accurate calculations, and quick generation of reports. These tools often include digital image capture and 3D rendering capabilities, enabling detailed visual assessments remotely.

Furthermore, integrating specialized training programs can empower estimators to make quicker decisions. Teaching them to recognize common damage patterns and materials reduces the time spent on individual component analysis. This, coupled with efficient communication between estimators, technicians, and parts suppliers, creates a seamless workflow that streamlines autobody repairs, fender repair, and automotive restoration processes, ultimately benefiting both the shop and its customers through faster turnaround times.

Leverage Technology for Accurate, Rapid Evaluations

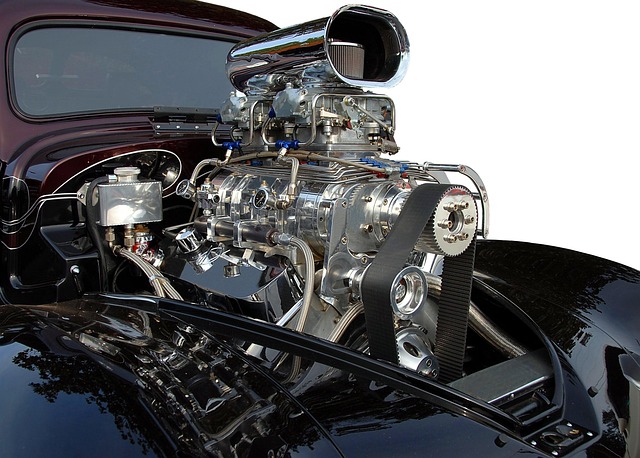

In today’s digital age, technology plays a pivotal role in enhancing efficiency within direct repair programs (DRPs). Advanced software tools and applications are designed to streamline the estimation process, enabling auto body shops to deliver faster and more accurate evaluations. These technologies offer a range of benefits, from automating time-consuming tasks to providing real-time data access. For instance, digital estimating platforms can quickly pull up historical repair records, ensuring that every detail is accounted for in the latest estimate. This not only saves technicians’ valuable time but also improves the overall accuracy of repairs, especially when dealing with complex procedures like auto glass replacement or intricate dent repairs.

By implementing these technological solutions, automotive body shops can significantly reduce the time spent on paperwork and manual calculations. This results in faster turnaround times for customers, allowing them to get back on the road sooner. Moreover, technology provides a consistent and standardized approach to estimating, which is particularly beneficial when comparing quotes across different repair facilities. This standardization ensures that every customer receives a fair and transparent estimate, fostering trust in the DRP process.

Improving estimate speed in a direct repair program (DRP) involves a strategic approach that combines understanding of DRP requirements, process optimization, and leveraging technology. By streamlining operations and embracing innovative tools, you can significantly enhance evaluation accuracy while reducing turnaround time. This not only benefits your business by increasing efficiency but also improves customer satisfaction through faster service.