Accurate documentation is key for successful direct repair programs (DRPs) in automotive restoration, ensuring transparency and efficiency. This method enhances speed and precision, reduces costs for businesses and customers alike, and serves as a powerful risk mitigation tool with detailed records from initial assessment to final installation, protecting both mechanics and vehicle owners.

In the realm of repair management, accurate documentation is not just a best practice—it’s a cornerstone. This article delves into the critical role of meticulous records in enhancing the efficiency and effectiveness of direct repair programs. We explore why detailed documentation matters, from streamlining workflows to mitigating risks and ensuring compliance. By understanding these principles, you’ll uncover strategies to optimize your repair processes and safeguard against potential challenges.

- Accurate Documentation: The Cornerstone of Repair Programs

- Enhancing Efficiency: Why Direct Repair Matters

- Mitigating Risk: Safeguarding Through Detailed Records

Accurate Documentation: The Cornerstone of Repair Programs

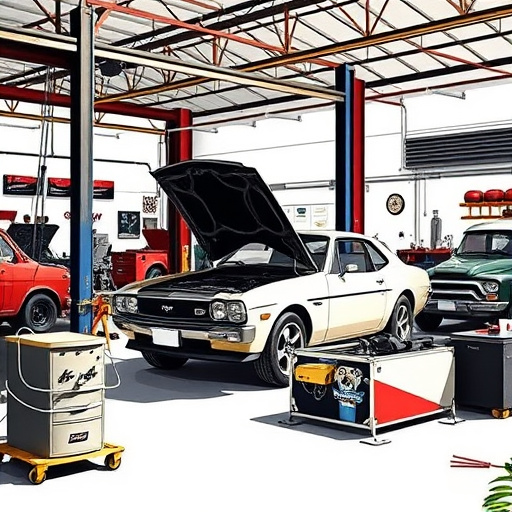

Accurate documentation is the cornerstone of any successful direct repair program (DRP). In the complex world of auto body repair and automotive restoration, meticulous record-keeping ensures that every step of a car damage repair process is accounted for, from initial assessment to final inspection. It provides a clear, detailed picture of the work performed, parts replaced, and techniques employed.

This level of documentation goes beyond simply maintaining records; it facilitates effective communication between repair facilities, insurance providers, and vehicle owners. Accurate DRP documentation allows for precise tracking of repairs, helps in dispute resolution, and ensures that every party involved has a comprehensive understanding of the car’s current state and history of repairs, fostering transparency and trust throughout the auto body repair process.

Enhancing Efficiency: Why Direct Repair Matters

Implementing a direct repair program can significantly enhance efficiency across various aspects of automotive maintenance and restoration. Traditional methods often involve extensive processes, with parts needing to go through multiple hands before reaching the workshop floor. This not only delays repairs but also increases the risk of errors or miscommunication. A direct repair approach streamlines this process by allowing specialized technicians to handle each step, from initial assessment to final installation.

By adopting a direct repair program, car restoration and vehicle dent repair processes become more manageable and faster. It ensures that every repair, whether it’s a simple dent removal or complex engine overhaul, is executed with precision and expertise. This efficiency translates into cost savings for both businesses and customers, making it an attractive strategy in the competitive automotive industry, including the realm of automotive repair.

Mitigating Risk: Safeguarding Through Detailed Records

In the realm of automotive repair, especially within direct repair programs, accurate documentation is a robust risk-mitigation strategy. Detailed records serve as a safeguard against potential disputes and ensure that every step of the repair process is transparent and traceable. When a vehicle arrives at the workshop, whether it’s due to a fender bender or needing comprehensive car bodywork services after a more severe collision, meticulous documentation begins. This includes recording initial assessments, detailed photographs, and precise descriptions of the damage.

As repairs progress, regular updates and revised assessments are documented, providing a clear timeline of work performed. Such thorough records enable mechanics to justify their actions and ensure customers understand the repair process. In the event of any discrepancy or claim, these documents serve as concrete evidence, protecting both the repair shop and the vehicle owner, thus fostering trust in vehicle collision repair services.

Accurate documentation is the linchpin of successful repair programs, fostering efficiency and mitigating risk through detailed records. By adopting practices like comprehensive data collection and standardized reporting, organizations can ensure seamless operations and customer satisfaction within their direct repair programs. This strategic approach not only streamlines processes but also safeguards against potential issues, ultimately enhancing the reliability and reputation of the program.